PRODUCTS

Oil seal installation requirem

HOME - PRODUCTS - Oil seal installation requirem

PTFE oil seal installation requirements and instructions at a high speed

Installation requirements

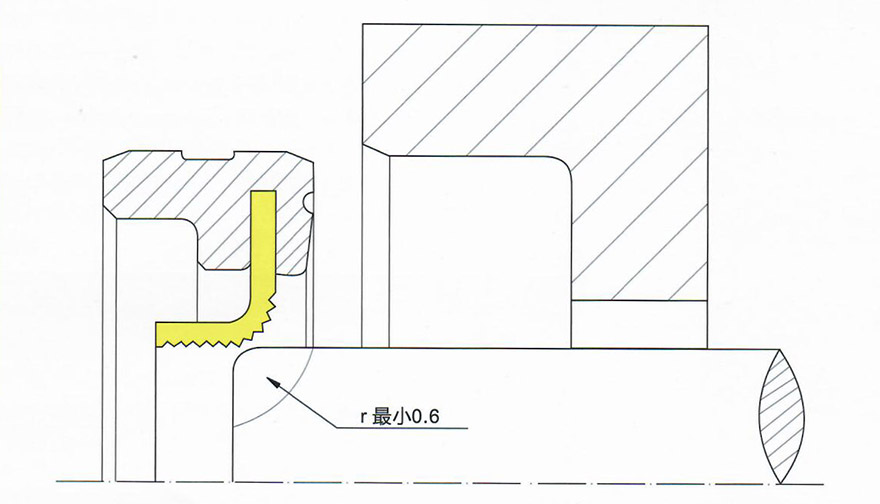

When installing a high-speed PTFE oil seal, in order to avoid damage the sealing lip, the most important thing is to be careful operation. If the seal installation, from behind in the shaft end must be round chamfer or the introduction of chamfering processing. At the same time must be no burrs, sharp corners or rough processing lines, as shown in the figure below.

When make the lip on the shaft end seal installation, requires the introduction of chamfering of minimum diameter is less than the diameter of the sealing lip not force, as shown in the figure below.

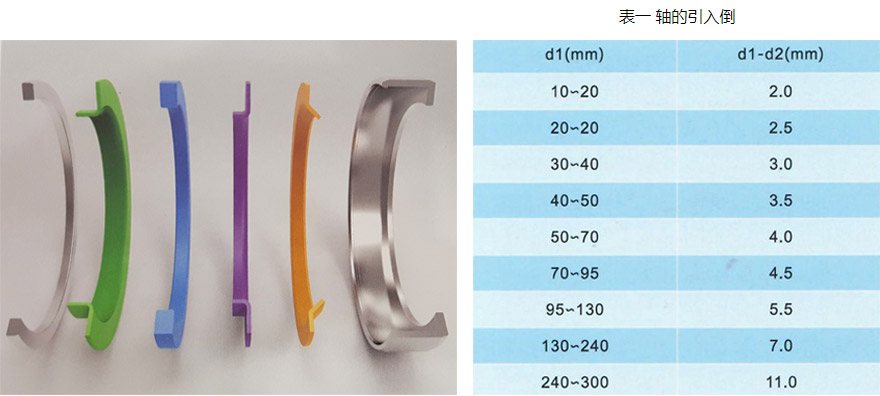

Table 1 gives about the introduction of Angle guide.

Suggested that in the given range, the actual use shallow angles.

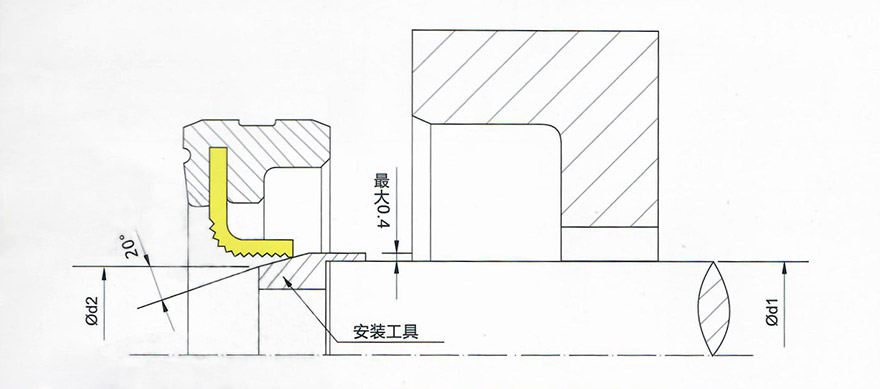

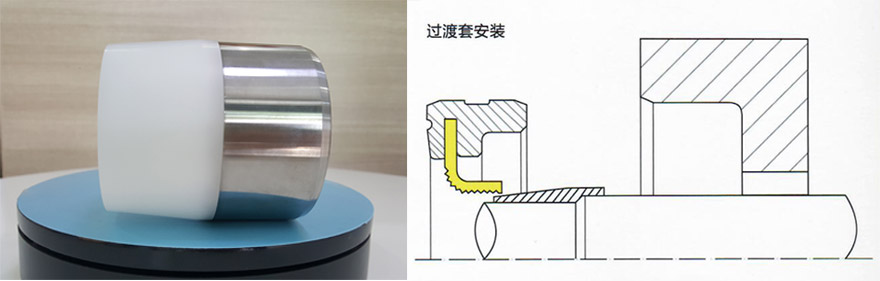

Reverse installation guide the installation method of first selection is used set, as shown in the figure below, the seals before loading axis can be installed on the guide outfit set, to ensure the sealing lip correct positioning.

Installation shall promptly, so that can reduce the deformation of the sealing lip on the taper sleeve, thus reduce lip recovery time.

Installation instructions

According to a survey by high-speed PTFE oil seal failure in advance, a large proportion of the is due to improper installation method.

Recommended according to the following guide to install, therefore, to the greatest degree avoid this early failure caused by improper installation.

The recommended installation process

Shall regularly check the guide sleeve and installation tools.

It was not until before installation to take out when oil seal from the supply side skirts. Watch out when remove the conical skirts, don't increase the deformation of the flange diameter.

Seals shall be adopted into type installation, pay attention to the required pressure into the force point circular uniform and close to seal the outer diameter of as much as possible.

If the seal dynamic pressure characteristic exists in the sealing lip (screw back into the tank). Should ensure that along the axial direction of rotation will be lip import.

Normal operation is to seal lip toward to seal medium. (only when ruled out medium is more important than keep medium, it will be to seal, in turn, installation).

In applications requiring strong sealing or bad, you can use a dedicated seal glue or adhesive to improve the overall diameter of seal.

Total0Page0Records